water vapor permeability test cup department Store|water vapor permeability chart : factories Perm cups are used to determine the permeability of films to the vapor of water and other liquids including paint, varnish, thin plastic films and other types of sheets thin enough to be .

15 de abr. de 2023 · Todas Atividades. Home. Cheats Premium. Serviços Pagos. Serviços Pagos - Conteúdo Adulto. [VIDEO] JuhMorena. A Cheats informa que não se responsabiliza por ter menores entrando na área adulta +18, caso acesse e seja menor de 18 fica na sua inteira responsabilidade o que visualizar nessa área.

{plog:ftitle_list}

webSamsof Technologies . We are a Philippines based purveyor of services and products for electronic infrastructures in the manufacturing and technology industries.

TQC Sheen permeability cupsconsist of a cup, a seal ring and a cover ring. The seal ring is designed to prevent turning when closing the cover. See moreOur permeability cupsare suitable for testing both self-supporting coatings and non-self-supporting coatings. See moreThe TQC Sheen range of permeability cupsis designed to support testing to a number of international standards, including ISO 7783,ASTM D1653and ASTM E96. See moreAcross the Industrial Physics portfolio we have a wide range of paint testing instruments and accessories to offer. For example, create a dazzling array of illumination conditions to inspect and color match many types of materials and coatings using our brilliant color assessment cabinets. The TQC Sheen Dew Point calculatoris a handy tool to determ. See more

We’re always pleased to share the knowledge we’ve gained over decades of making devices to test inks and coatings. In the knowledgebase section of our websiteyou’ll find blogs about subjects related to the product on offer on this page. For example, this one explores how to assess car paint quality.Or perhaps you’d consider this blog that asks . See morePerm cups are used to determine the permeability of films to the vapor of water and other liquids including paint, varnish, thin plastic films and other types of sheets thin enough to be .

The “dry cup” method involves utilizing a desiccant within the test cup and maintaining 50% RH in the ambient chamber. Water vapor is expected to diffuse into the cup (i.e., the cup’s mass will increase over time), and the mass .The EZ-Cup Vapometer is used to measure water vapor permeability. The Vapometer consists of a lightweight aluminum cup and an aluminum threaded flanged ring with two neoprene .

Cup method is the method used to test water vapor permeability independently based on a simple and perspicuous principle. In cup method, there is certain pressure difference . Detailed video explanation of ASTM E96-22 standard desiccant and water test methods for water vapor transmission rate of materials. The water vapour permeability test measures how well fabrics let moisture through. It does this at different temperatures and humidities. It simulates how well fabrics move water vapor. Bodies release it when they .

Two of the methods to test the water vapor transmission of a material are desiccant (dry cup) and water (wet cup). These two tests are similar in setup but the service conditions are .Permeability is measured with wet-cup, dry-cup, or modified cup tests. Specific test methods for measuring water vapor permeability are given in ASTM Standard E96. For many engineering materials, vapor permeability is a strong .The test evaluates the water vapor transfer through semi-permeable and permeable samples. The data can be used by manufacturers and designers and is often important in packaging .

The basis of the ASTM E96 method for WVP is measuring the mass loss from the cup over time (Q/t) while controlling the other parameters of the equation.To do so, the cup is placed in a cabinet kept at 0% relative humidity (RH) by fans moving air at a speed of 152 m min −1 to assure constant and complete wipeout of water vapor coming out of the film top surface [], while the . These are cups designed to test the properties of polymer plastic films. I use it to test the moisture barrier performance of biofilms. The cups are filled with either water (or dessicant), and the sample loaded in between the .

The volume of the cup is 10 milliliters; Normal test weight of the cup assembly is less than 88 grams . Perm cups are used to determine the permeability of films to the vapor of water and other liquids including paint, varnish, thin plastic films and other types of sheets thin enough to be tightly sealed in place across the face of the cup.

Water vapor permeability is one of the main performance indexes of package materials. As people are attaching more importance to the damp proofing and waterproofing of products, package materials with smaller water vapor permeability becomes the f.3us of package material development and application and is receiving more and more concentrations in recent years. The water vapour permeability is a material property used in calculations of the hygrothermal performance of buildings. The standard test method (the 'cup test'), little changed for decades and .The permeability cup (wet cup) is a great way to determine water-vapor transmission. What does a permeability cup consist of? TQC Sheen permeability cups consist of a cup, a seal ring and a cover ring. The seal ring is designed to prevent turning when closing the cover. Permeability testing for different coatings

water vapor permeability chart

Permeability of Common Building Material to Water Vapor WHAT IS A PERM RATING? If a material has a perm rating of 1.0, 1 grain of water vapor will pass through 1 square foot of the material, provided that the vapor pressure difference between the cold side and the warm side of the material is equal to 1 inch of mercury (1 inch Hg).

This standard has been approved for use by agencies of the Department of Defense. 1. Scope 1.1 These test methods cover the determination of water vapor transmission (WVT) of materials through which the passage of water vapor may be of importance, such as paper, plastic films, other sheet materials, fiberboards, gypsum and References [1] K. Hansen, N. Bertelsen, Results of a Water Vapor Transmission Round-Robin Test Using Cup Methods, Water Vapor Transmission Through Building Materials and Systems: Mechanisms and Measurement, ASTM STP 1039, H.R. Trechsel and M. Bomberg, Eds., American Society for Testing and Materials , Philadelphia, 1989, pp. 91–100. [2] S. The water vapour permeability test measures how well fabrics let moisture through. It does this at different temperatures and humidities. It simulates how well fabrics move water vapor. Bodies release it when they sweat. They release it to the outside. Moisture permeability is the quality of water vapor transfer on both sides of the fabric.

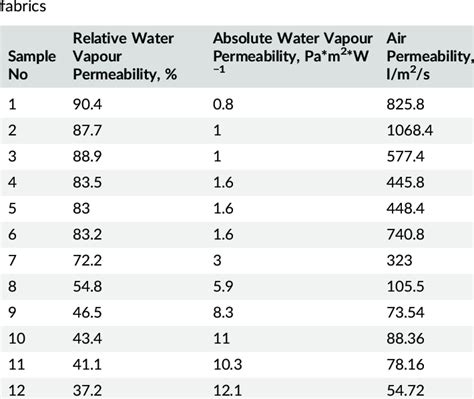

Five testing instruments plus a new test apparatus were employed to evaluate the water vapor transport properties of fabrics with low, medium, and high vapor permeability. The test results show that the desiccant inverted cup method generated the highest water vapor transmission rate, followed by the new method, the dynamic moisture permeation .

Water vapor permeability of building materials is usually measured using dry cup test according to the ISO 12572 standard. For this test, suitable adsorbing desiccant should be used to provide .Two of the methods to test the water vapor transmission of a material are desiccant (dry cup) and water (wet cup). . The water method assembly measures weight loss due to water vapor from the cup transmitting through the material to the test atmosphere as well as the humidity of the test chamber. . *Permeability calculation: Permeance = WVT . water vapor transmission rate Ñthe steady water vapor ßow in unit time through unit area of a body, normal to speciÞc parallel surfaces, under speciÞc conditions of temperature and humidity at each surface.Ó 4. Summary of Test Methods 4.1 In the Desiccant Method the test specimen is sealed toThe inside of the wet cup is near 100% relative humidity (a higher vapor pressure than the chamber), and the inside of the dry cup is near 0% (a lower vapor pressure than the chamber). Physics being physics, the wet cup will lose .

The EZ-Cup Vapometer is used to measure water vapor permeability (WVTR). The Vapometer consists of a lightweight aluminum cup and an aluminum threaded flanged ring with two neoprene gaskets with a Teflon seal that . K. Hansen, N. Bertelsen, Results of a Water Vapor Transmission Round-Robin Test Using Cup Methods, Water Vapor Transmission Through Building Materials and Systems: Mechanisms and Measurement, ASTM .

The rate of water vapor transfer for fabric, coated fabrics, composite, clothing, industrial textiles, etc. is ascertained using the water vapor permeability test. Water Vapor Permeability Tester Equipped with a 500×500×500mm chamber and a customized air flue to regulate temperature, humidity, and wind speed, our machine typically comes with .

ASTM D 1653 is a standard test method used to determine the permeability of organic coatings to water vapor and gases. The test involves immersing coated test panels in water or other liquids, and measuring the rate of water vapor or gas transmission through the coating. the author analyzes influencing factors of water vapor permeability testing methods for plastic films (package). Meanwhile, some suggestions for improvement are put forward. Key Words: water vapor permeability, water vapor transmission rate, cup method, sensor method, desiccant method and water method 1.Overview:

tqc permeability cups

This standard has been approved for use by agencies of the U.S. Department of Defense. 1. Scope 1.1 These test methods cover the determination of water vapor transmission (WVT) of materials through which the passage of water vapor may be of importance, such as paper, plastic Þlms, other sheet materials, Þberboards, gypsum and

By studying various test methods of water vapor transmission rate, Labthink manufactures many water vapor permeability testing instruments based on ASTM E96/GB 1037 (gravimetric method), ISO 15106-2/ASTM F1249 (infrared sensor method), ISO15106-3 (electrolytic sensor method) and ISO15106-1/ASTME398 (humidity sensor method). Labthink has the .Water vapor permeability is a measure of the passage of water vapor through a material. It is also known as water vapor transmission rate (WVTR) or moisture vapor transmission rate (MVTR) - which is basically the mass of water vapor that is transmitted through a measured area in a specific unit of time under specified conditions of temperature and humidity.Where 2WVT (kg/m .S), μ is water vapor permeability and a function of relative humidity (RH) and temperature (T), ΔP is change in water vapor pressure and ΔX is change in the distance. In a study conducted by Kumaran [6], it was observed that the water vapor permeability of the

Paperboards were subjected to WVTR test for 7 days at 22°C temperature, 55% humidity and 42°C temperature, 85%humidity values using Thwing-Al-bert EZ-Cup Vapometer Permeability Cups.for water vapor it is given in units of mass of water vapor. Sometimes, the amount of permeant is given in moles. Sometimes the term “diffusion coefficient” is used incorrectly instead of permeability, which are different properties, leading to additional confusion. Another complication involves the water vapor transmission rate (WVTR).Because of the different partial vapour pressure between inside the test cup and the chamber, a vapour flow occurs through permeable test specimens. The set sample-cup is weighted in order to determine the water-vapour transmission properties when stationary state is reached. Water- vapour transmission rate V (g/m2d): The mass of water that is

Resultado da 1 de jun. de 2023 · Deadloch: Created by Kate McCartney, Kate McLennan. With Kate Box, Madeleine Sami, Alicia .

water vapor permeability test cup department Store|water vapor permeability chart